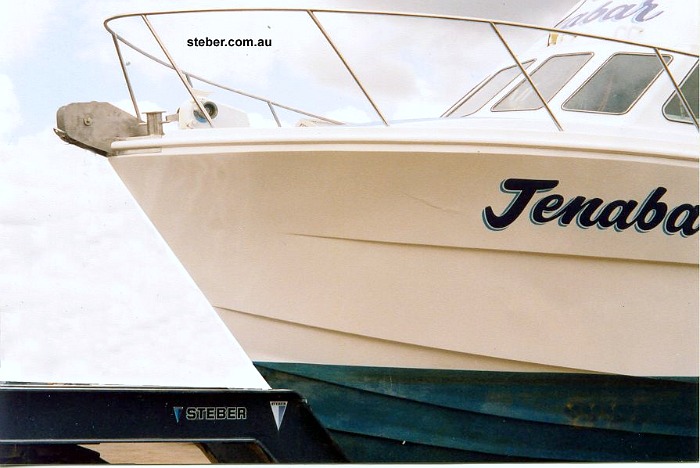

Year after year Steber International is asked by owners of many different types to vessels to either repair damage or return others to their former glory.

Whether your boat is an original Steber or other brand, Steber International can offer an extensive range of marine & FRP services to a wide range of marine applications & composite components.

Repairs, maintenance &/or refits can be carried out on site, off site, on slip or in factory premises by a skilled staff, to Quality Assurance standards.

Steber International has over 50 staff with all on site work being carried by our well credentialed team meaning faster turnaround times. Costs are kept lower due to the fact that our vast factory storage space is far more economical than traditional on water slipways.

Quotations or estimates can be provided.

Brochure download ReUse-ReNew-ReFit

With over 65 years experience in the Marine Industry, specialising in the manufacture of surveyed vessels, our expertise includes but is not limited to:

Fibreglass product manufacturing is the cornerstone of Steber International and so it is little wonder that boats received with either light or harsh damage are repaired to “As new” level.

You can see from the before and after examples the quality of workmanship and why you should strongly consider appointing Steber to repair or maintain your vessel.

With in excess of 30 years experience in manufacturing surveyed vessels, ranging in size from 28ft to 52ft, it is a simple procedure to re-survey vessels or up-grades on existing surveyed craft to a higher category. Our long experience and commitment with testing equipment, specialized staff, Surveyors and Naval Architects and close association with all Government Authorities, ensures complete customer satisfaction.

Removal of old engines, upgrading engine room, re-fit of associated plumbing and equipment prior to installing engines is all part of the Steber re-power procedures. Engineering calculations of shafting, propellers, bearings etc. all contribute to a professional, well planned, re-engine installation that a customer will be proud of.

Motor and Gen Set servicing is generally carried out by a local service agent in the home port of the owner. If you are not satisfied with the local service agent, Steber International can arrange alternate servicing and spare parts closest to the engine manufacturer as well as overseeing the technician to meet private or Government servicing requirements.

During the 35 years of Motor Cruiser production, Steber International have installed many single or twin jet powered vessels, in fact 2 of the late Kerry Packer’s 40ft chase boats were re-engineered at the Steber factory by removing sterndrives and fitting water jets, with over 40 knot top speed and very little maintenance, the crew are delighted with this vessel. Steber International approach every project by obtaining the right advice from the Jet manufacturer to ensure best performance.

Engineering records for all craft manufactured at the Steber International factory are stored (archived) for later retrieval. Engineering upgrade via re-powering, or just improving engineering with the latest technology is a simple process for Steber International. Following the upgrade, new certificate for engineering will be issued to the owner and once again, records are stored for future retrieval. All non Steber vessels can also be catered for and over the years Steber has re-fitted many vessels with great success.

Steber International quote on all components on a supply only or to supply and install. CAD drawings are kept on file for most stainless steel and alloy fabricated equipment, holding a Copyright. Steber International therefore can guarantee complete quality replacement facility or can measure and draw new equipment to owner’s requirements. All marine quoted engineering is backed up by a prompt delivery service.

A full carpentry and cabinet machining workshop is located on site. Acrylic bench tops are CNC machined on site. High grade glass finish with full polish facility is available or if a hard wearing white laminate marine ply finish is required, all

second to none.

Teak and cork decking is contracted and installed within our factory by our well trained staff. Repairs to teak and cork decking can also be carried out in house. Sanding and rejuvenating of decking is a special service carried out by the factory team as well as re-corking.

Within the factory is a complete one stop upholstery shop. The upholsterer carries out all sound insulation linings, vinyl, tapestry and leather upholstery, curtains and full screens, all in house. Steber International can arrange contractors at your local port to install and/or repair all upholstery items.

With fully qualified marine technicians, the installation of a vast range of marine electronics can be installed on all vessels ranging from a simple pleasure craft to a complicated Police/Rescue vessel or Hydrographic Survey vessel. Steber International have close relations with all marine electronic suppliers and can arrange for a full supply and fit quotation for any vessel within Australia, and in fact around the world.

Preferred fire protection system suppliers are on hand and can be deployed to service, upgrade, install or renew to an existing craft. Most makes and models can be supplied to meet the survey rules and regulations for complete satisfaction.

Earthing of stray current, identifying critical areas for poor earthing is difficult but not impossible. Protection and monitoring equipment can be supplied and installed by Steber International, who have gained vast experience over the years and have been trained by Marine Corrosion Protection systems to ensure best practice.

Steber International have customized fit-out of their vessels for over 30 years. With full CAD facilities including 3D RHYND software, any customer, including Government Departments can request and approve a special fitout prior to installation, therefore reducing costs. Any make and model of vessel can be catered for delivering a fit out to meet your expectations.

Steber International can arrange a complete strip and re-antifoul facility at your Australian East Coast local port. If motoring on the east coast, a short stay at either Forster or Crowdy Head slipways, Steber International can complete all your boating needs.

Download Colin Woods full details